Design and style and Programming: Engineers get started the design phase by using CAD software program to build a 3D model of their ideal component. After finishing this phase, engineers transform this file to CNC-appropriate structure ahead of sending it off for plotting on CAM software, in which paths for your machining tools is going to be marked out prior to being uploaded specifically on to a CNC machine.

Cutting tools are of numerous dimensions and styles In line with the necessities. The followings are definitely the common samples of milling cutters.

CNC machining presents its use on many medically Safe and sound materials. Since the procedure is suited to 1-off custom parts, it has numerous applications during the professional medical industry. The limited tolerances afforded by CNC machining are essential to the higher performance of machined medical parts.

Moreover, it's got offered the opportunity to make tools for prototyping, resulting in immediate prototyping and fast tooling. Swift prototyping gives the ability to build prototypes with A fast turnaround time.

Due to in depth variety of applications, CNC precision machining requires an array of machinery and equipment. Allow me to share the machinery and equipment:

Metals: Metals for example aluminium, metal, titanium and copper are used due to their durability, strength and versatility. Every single metal boasts special characteristics; aluminium’s lightweight nature may well appeal to some, when titanium presents strength and corrosion resistance, by way of example.

Applying these superior-precision equipment inside your production course of action will without doubt bring quite a few Advantages. Large-precision Kovosvit MAS CNC equipment machining is easily the most Expense-powerful possibility, particularly if you only require a couple to a hundred merchandise.

Headquartered in China, in excess of a CNC shop, we will also be a responsible supplier who stocks all sorts of materials and features numerous finishing possibilities on your own demand from customers.

I Machine Tools-branded merchandise created up over 40 with the shipments to I Machine Technology previous 12 months, together with some that came by using Turkey and China, according to Russian import records. Only quite a few ended up for parts, the information suggest.

The method also eliminates the necessity for guide assembly and increases the production pace in comparison to traditional methods. Once the design is entire, the part might be tested and evaluated for use in automotive applications. The hybrid manufacturing procedure allows corporations to cut back prices even though generating high-quality parts quickly and efficiently.

Anodizing: A means of forming a layer of oxide movie on aluminum goods, to overcome the defects of aluminum alloy area hardness and put on resistance.

Aerospace: Precision is crucial in aerospace to be sure basic safety and functionality. CNC machining makes intricate parts for aircraft engines, landing gears, and also other vital components.

The food and beverage industries aren’t the very first assumed that comes to head when thinking about CNC machining. However, these industries count seriously on CNC in a variety of places.

As we approach the 2030s, the die and mould industry will take advantage of more improvements in multi-axis machining and significant-pace CNC technology.

Danny Tamberelli Then & Now!

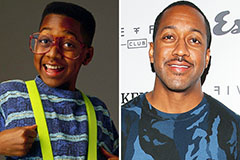

Danny Tamberelli Then & Now! Jaleel White Then & Now!

Jaleel White Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now!